| Home | Projects | Car | About |

|

Modified Technics SL-1200MK2  When a deejay is searching the market for a turntable, there is one icon which immediately comes to mind: the Technics SL-1200MK2. This project write-up details the steps I took to modify and improve my own two decks.

When a deejay is searching the market for a turntable, there is one icon which immediately comes to mind: the Technics SL-1200MK2. This project write-up details the steps I took to modify and improve my own two decks. Instead of buying the decks new (which command a hefty price tag of about $459) I purchased both of my used from eBay for $135 and $113. Here, one of them is displayed in the state I received it.

Instead of buying the decks new (which command a hefty price tag of about $459) I purchased both of my used from eBay for $135 and $113. Here, one of them is displayed in the state I received it. Considering I paid close to a fourth of the retail price, the decks were in decent condition aside from some marks and scratches. A close-up shot of the $135 deck shows lots of dust and grime both inside and around the platter area.

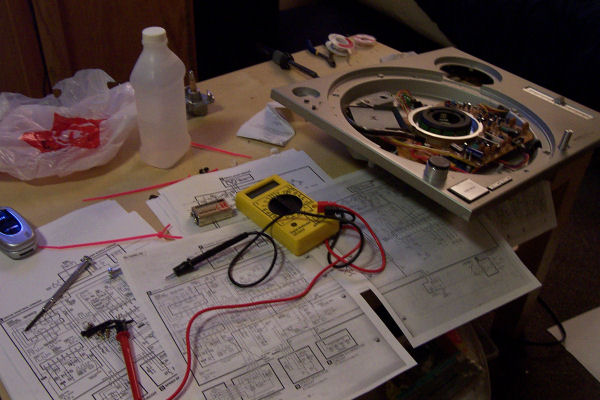

Considering I paid close to a fourth of the retail price, the decks were in decent condition aside from some marks and scratches. A close-up shot of the $135 deck shows lots of dust and grime both inside and around the platter area. To get started on the modifications, both turntables had to be fully disassembled. This photo shows one of them on display.

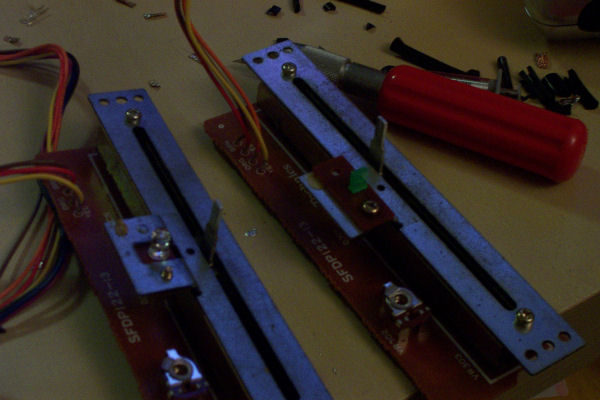

To get started on the modifications, both turntables had to be fully disassembled. This photo shows one of them on display. First modification: blue LEDs will be installed in the strobe light and pitch faders. These were purchased online in both 3mm and 5mm packages from LSDiodes, whom unfortunately no longer sells them.

First modification: blue LEDs will be installed in the strobe light and pitch faders. These were purchased online in both 3mm and 5mm packages from LSDiodes, whom unfortunately no longer sells them. Soldering new 5mm LEDs in the strobe light. There are four of them which replace the old red ones.

Soldering new 5mm LEDs in the strobe light. There are four of them which replace the old red ones. There was not enough clearance above the pitch sliders to install 5mm LEDs. Instead, 3mm LEDs were installed. The PCB had to be relocated to the bottom of the mounting bracket to make a little extra height for the LED.

There was not enough clearance above the pitch sliders to install 5mm LEDs. Instead, 3mm LEDs were installed. The PCB had to be relocated to the bottom of the mounting bracket to make a little extra height for the LED. Second modification: the pitch fader on the less expensive deck was defective in that it did not engage the “quartz lock” circuitry or light. Additionally, it caused strange fluctuations in the pitch right around the -6% mark. Rather than pay upwards of $30 + shipping for a replacement pitch fader, I decided to repair the current one with a windshield-defogger repair kit, a common and easy-to-find source for conductive paint. I have already used this type of paint successfully for many applications, including CPU overclocking and video card volt-modding.

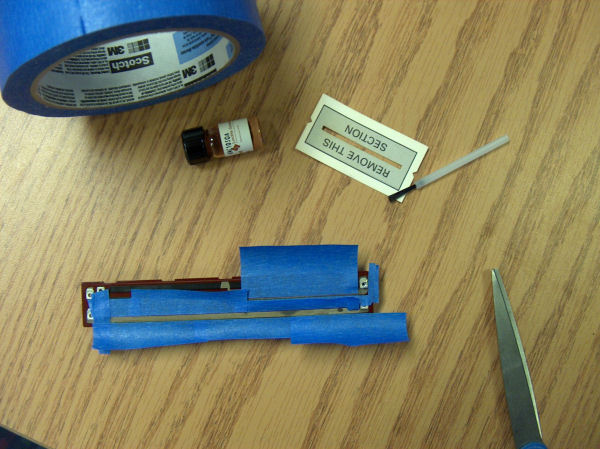

Second modification: the pitch fader on the less expensive deck was defective in that it did not engage the “quartz lock” circuitry or light. Additionally, it caused strange fluctuations in the pitch right around the -6% mark. Rather than pay upwards of $30 + shipping for a replacement pitch fader, I decided to repair the current one with a windshield-defogger repair kit, a common and easy-to-find source for conductive paint. I have already used this type of paint successfully for many applications, including CPU overclocking and video card volt-modding. This repair works because two of the conductive traces which act as regular wires were defective. The “quartz lock” trace (found in the middle) was severed, and the “pitch fader return” trace (found at the bottom) had worn away at the -6% mark. Note this repair cannot be performed on the light grey variable-conductance plastic strip, which acts like a resistor to measure the pitch. To begin the repair, first mask off conductive trace in need of fixing (I used painters tape for this).

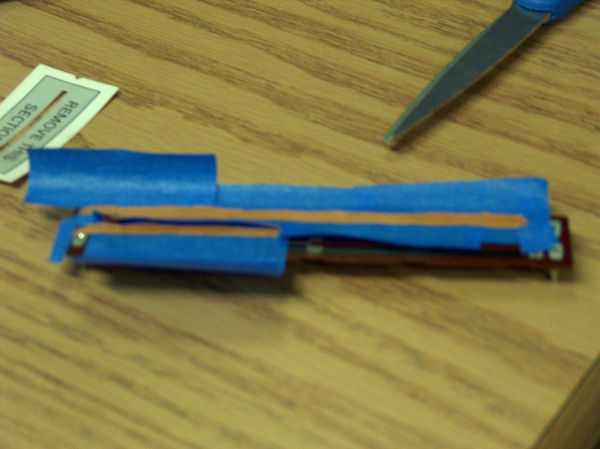

This repair works because two of the conductive traces which act as regular wires were defective. The “quartz lock” trace (found in the middle) was severed, and the “pitch fader return” trace (found at the bottom) had worn away at the -6% mark. Note this repair cannot be performed on the light grey variable-conductance plastic strip, which acts like a resistor to measure the pitch. To begin the repair, first mask off conductive trace in need of fixing (I used painters tape for this). The conductive paint, applied and drying.

The conductive paint, applied and drying. Testing the traces showed roughly 24 ohms of resistance. This is close enough to full conductivity (0 ohms) to be successful.

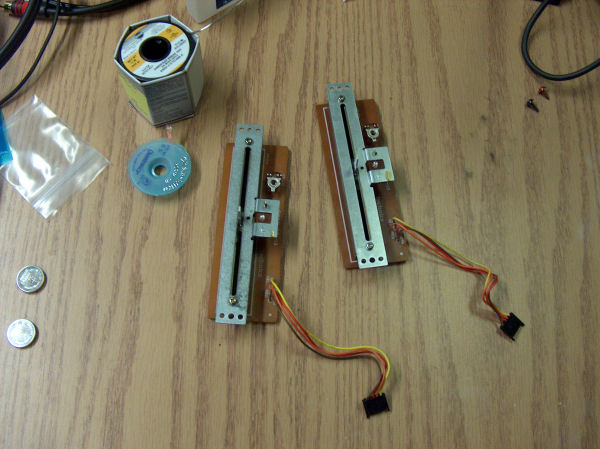

Testing the traces showed roughly 24 ohms of resistance. This is close enough to full conductivity (0 ohms) to be successful. Both faders are now fully functional, with the 3mm blue LEDs installed.

Both faders are now fully functional, with the 3mm blue LEDs installed. Second modification: my next step was to replace the yellowish pop-up light bulbs with LEDs.

Second modification: my next step was to replace the yellowish pop-up light bulbs with LEDs. Bright white LED were harvested from a cheap head-mountable LED flashlight.

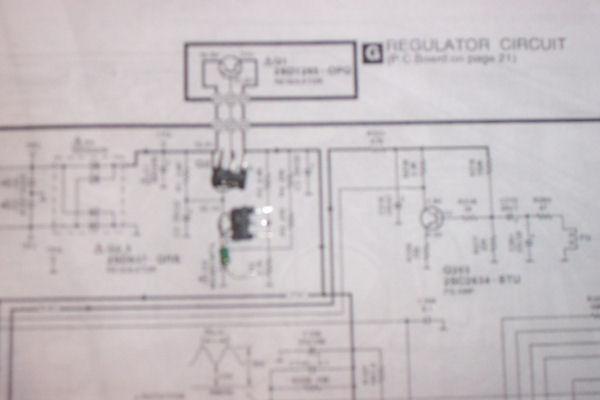

Bright white LED were harvested from a cheap head-mountable LED flashlight. A single 5mm LED can be used to replace the pop-up light. However, a quick look at the SL-1200MK2 service manual (which can be found here courtesy of the Vinyl Engine) shows the 20V input will quickly destroy the roughly 3V LED. To fix this, a single 680 ohm resistor had to be spliced in-line with any of the wires around the bulb. The resistor currently attached to the switch should be replaced with something substantially larger (~1 megaohm) to prevent the LED from turning on when the switch is open. In my case, I just decided to remove it.

A single 5mm LED can be used to replace the pop-up light. However, a quick look at the SL-1200MK2 service manual (which can be found here courtesy of the Vinyl Engine) shows the 20V input will quickly destroy the roughly 3V LED. To fix this, a single 680 ohm resistor had to be spliced in-line with any of the wires around the bulb. The resistor currently attached to the switch should be replaced with something substantially larger (~1 megaohm) to prevent the LED from turning on when the switch is open. In my case, I just decided to remove it. The first of the LED pop-up lights. This one needed to have the rubber stopper re-glued as it was coming off.

The first of the LED pop-up lights. This one needed to have the rubber stopper re-glued as it was coming off. Joel over at the Turntable Factory was a great resource, as he explained the simplest way to fix the rubber stopper was using super glue. Here you can see it curing in place.

Joel over at the Turntable Factory was a great resource, as he explained the simplest way to fix the rubber stopper was using super glue. Here you can see it curing in place. Preliminary testing of the LEDs, which turned out to be less successful then the picture suggests. After repeatedly pushing the pop-up lamp up and down on one of the decks, I seemed to have shorted the LED leads together. This disaster probably could have been averted if I had used the 1 megaohm resistor I suggested earlier. Make sure you wrap the LED leads well in electrical tape when you modify the pop-up light!

Preliminary testing of the LEDs, which turned out to be less successful then the picture suggests. After repeatedly pushing the pop-up lamp up and down on one of the decks, I seemed to have shorted the LED leads together. This disaster probably could have been averted if I had used the 1 megaohm resistor I suggested earlier. Make sure you wrap the LED leads well in electrical tape when you modify the pop-up light! The result of the damage was two blown power regulation transistors, one shorted zener diode, and a completely non-functional turntable. You can see the three parts in the photo, placed on top of their respective locations in the service manual schematic.

The result of the damage was two blown power regulation transistors, one shorted zener diode, and a completely non-functional turntable. You can see the three parts in the photo, placed on top of their respective locations in the service manual schematic. Exact replacement parts were ordered from DJ Pro Audio, although a better and less expensive source would have been direct from Panasonic’s parts department. The parts were re-installed in after arriving in the mail, and they worked flawlessly.

Exact replacement parts were ordered from DJ Pro Audio, although a better and less expensive source would have been direct from Panasonic’s parts department. The parts were re-installed in after arriving in the mail, and they worked flawlessly. Third modification: after finishing the LED installations on both decks, I turned my attention to the tonearms. The lower bearings of the less expensive deck’s tonearm had been badly damaged, so a suitable replacement had to first be ordered from the Panasonic parts department. Following its arrival, I decided to rewire both the tonearms and replace the RCA cables with higher quality alternatives.

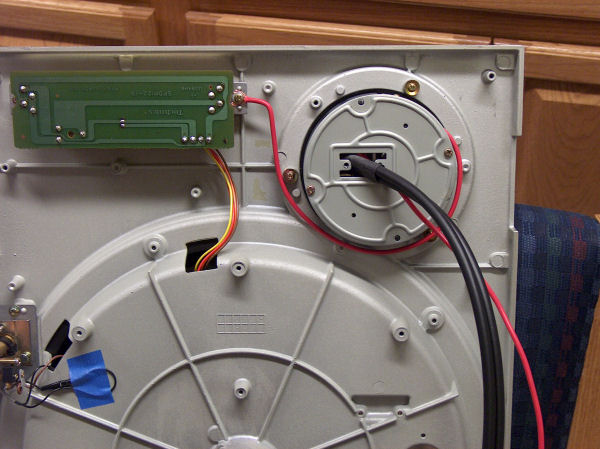

Third modification: after finishing the LED installations on both decks, I turned my attention to the tonearms. The lower bearings of the less expensive deck’s tonearm had been badly damaged, so a suitable replacement had to first be ordered from the Panasonic parts department. Following its arrival, I decided to rewire both the tonearms and replace the RCA cables with higher quality alternatives. Unfortunately, this is the only photo I have of the rewiring process (the rest were inadvertently deleted from my camera). The Cardas 4X33 Tonearm Wire was ordered from Take Five Audio. Although somewhat difficult to solder, each of the two pairs of copper signal wires were twisted-paired and covered by teflon + metal braid + rubber insulation layers. These wires replaced the stringy and inadequate original wires which ran from the headshell mount to the PCB at the base of the tonearm assembly. To allow the tonearm to move smoothly, all the layers had to be removed before passing the wires down from the arm. The braided shielding is collected and screwed underneath the grounding wire plate inside the arm shaft as well.

Unfortunately, this is the only photo I have of the rewiring process (the rest were inadvertently deleted from my camera). The Cardas 4X33 Tonearm Wire was ordered from Take Five Audio. Although somewhat difficult to solder, each of the two pairs of copper signal wires were twisted-paired and covered by teflon + metal braid + rubber insulation layers. These wires replaced the stringy and inadequate original wires which ran from the headshell mount to the PCB at the base of the tonearm assembly. To allow the tonearm to move smoothly, all the layers had to be removed before passing the wires down from the arm. The braided shielding is collected and screwed underneath the grounding wire plate inside the arm shaft as well. Since both turntables were covered in dust and grime, I decided to wash them in my bathtub. The outer shell, rubber base, and “weight plate” for both of the decks were immersed in warm, soapy bath water and a scrubbed clean with a sponge. Be cautious and use a non-abrasive sponge, as the deck surfaces will show the marks of a scouring pad.

Since both turntables were covered in dust and grime, I decided to wash them in my bathtub. The outer shell, rubber base, and “weight plate” for both of the decks were immersed in warm, soapy bath water and a scrubbed clean with a sponge. Be cautious and use a non-abrasive sponge, as the deck surfaces will show the marks of a scouring pad. A photo of me drying off a “weight plate”.

A photo of me drying off a “weight plate”. With the decks cleaned, final reassembly can begin. Here you can see the tonearm fully assembled, with upgraded ground and signal wires attached to the base. The ground wires were replaced with Belden 12-gauge 5000UE speaker wire from Blue Jeans Cable. Premium-quality RCA signal wires were purchased inexpensively from MonoPrice

With the decks cleaned, final reassembly can begin. Here you can see the tonearm fully assembled, with upgraded ground and signal wires attached to the base. The ground wires were replaced with Belden 12-gauge 5000UE speaker wire from Blue Jeans Cable. Premium-quality RCA signal wires were purchased inexpensively from MonoPrice A close up of the tonearm base. After reading this guide on Take Five Audio’s website, I decided to use inexpensive copper Cardas grounding spades and heatshrink for the ground wire.

A close up of the tonearm base. After reading this guide on Take Five Audio’s website, I decided to use inexpensive copper Cardas grounding spades and heatshrink for the ground wire. The turntables reassembled, with the platters removed. You can clearly see the new RCA cables and ground spades in the photo.

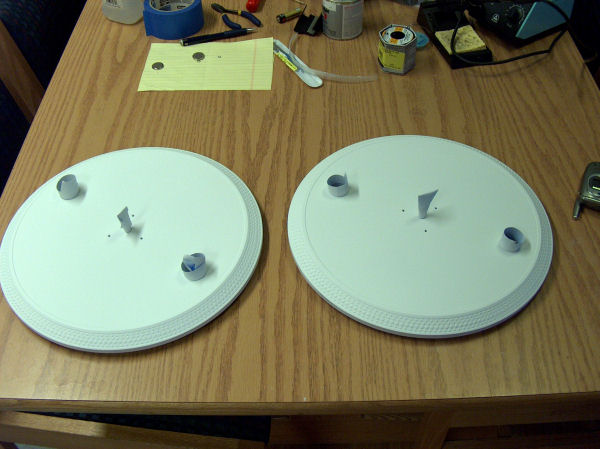

The turntables reassembled, with the platters removed. You can clearly see the new RCA cables and ground spades in the photo. Fourth modification: after reading kaype’s amazing Technics modifications here, I decided to follow his example of re-painting the platter markers. Since I wanted to make the entire platter white too, I first had to wet-sand away most of the black paint on the surface of the platter. To get the black paint out of the markers, I used a wire brush attachment on my cordless hand drill. Here you can see both platters after being painted flat white with spray paint. Do not use glossy paint (like I tried to do initially), because it will peel off during sanding.

Fourth modification: after reading kaype’s amazing Technics modifications here, I decided to follow his example of re-painting the platter markers. Since I wanted to make the entire platter white too, I first had to wet-sand away most of the black paint on the surface of the platter. To get the black paint out of the markers, I used a wire brush attachment on my cordless hand drill. Here you can see both platters after being painted flat white with spray paint. Do not use glossy paint (like I tried to do initially), because it will peel off during sanding. The platter markers had to be wet-sanded to reveal the aluminum finish. This was done with 600-grit sandpaper. To finish off the platter surface, it was wet-sanded with 1000-grit sandpaper until the “grab” was gone.

The platter markers had to be wet-sanded to reveal the aluminum finish. This was done with 600-grit sandpaper. To finish off the platter surface, it was wet-sanded with 1000-grit sandpaper until the “grab” was gone. A comparison of the platter markers before and after sanding. They look great!

A comparison of the platter markers before and after sanding. They look great! Both finished platters, ready to be placed on the decks. With the new paint job and the sticker gone, the platter surfaces have even more slip than the old black ones did!

Both finished platters, ready to be placed on the decks. With the new paint job and the sticker gone, the platter surfaces have even more slip than the old black ones did! Both turntables, fully assembled and turned on. The blue and white LED’s look great against the all-white platter.

Both turntables, fully assembled and turned on. The blue and white LED’s look great against the all-white platter. The decks with records on top. I use off-white “Frosted Plates” slipmats, which match the platters nicely when the vinyl is removed.

The decks with records on top. I use off-white “Frosted Plates” slipmats, which match the platters nicely when the vinyl is removed. A close-up of one deck with my Grado SR80 headphones from the Turntable Lab.

A close-up of one deck with my Grado SR80 headphones from the Turntable Lab. Both turntables installed in my Odyssey FZGSBM10 Glide Laptop Coffin from Pro Sound and Stage Lighting. I absolutely love the originality of the Technics paint job, plus it looks great with my white Asus notebook. Lets Mix!

Both turntables installed in my Odyssey FZGSBM10 Glide Laptop Coffin from Pro Sound and Stage Lighting. I absolutely love the originality of the Technics paint job, plus it looks great with my white Asus notebook. Lets Mix!Costs:

Top |